Find us at MACH 2024! 15th-19th

Stand 17-331, NEC Birmingham, NEC Birmingham

Turbex are returning to MACH 2024 – a showcase for UK Manufacturing. We’re excited to be sharing this event with the most prominent engineers and technology services in the manufacturing industry.

With over 25,000 visitors across the event, MACH is the perfect way to see the newest and best machines in action. Visit us at stand 17-331.

Looking to make new connections in the manufacturing industry? Sign up today here.

Turbex’s powerful range will be on display.

We offer a comprehensive roster of exceptional cleaning machinery, alongside more than 40 years of expertise to help you find the right solution.

Our machines provide precision cleaning, surface treatment, and depowdering for a range of industries; from aerospace and rail to medical and watchmaking.

At the event, you’ll be able to explore a range of our powerful machines in action:

Depowdering

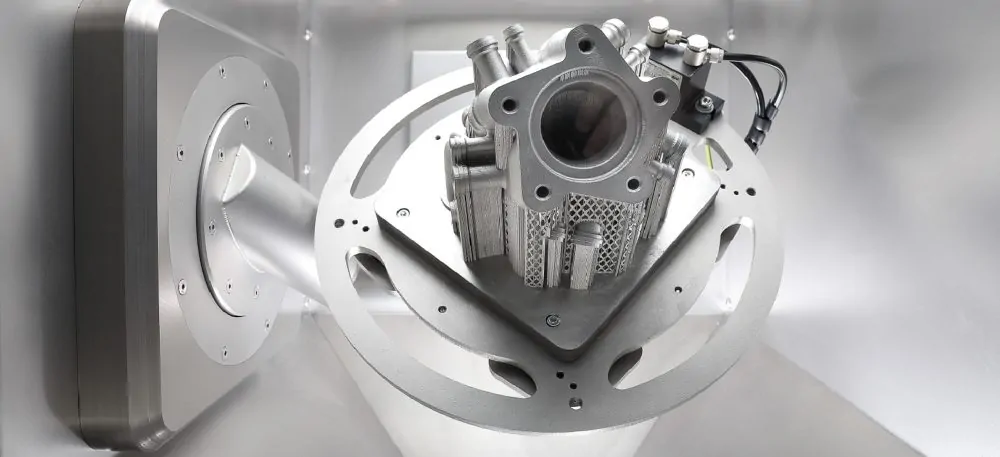

Solukon are the premier provider of depowdering solutions; they are true experts in the field of metal laser manufacturing. Their SFM-AT200 cleans metal laser-melted parts with a sealed process chamber, with targeted vibration and automated rotation to remove unmelted build material from complex voids. Plus, the compact structure of the SFM-AT200 optimises the footprint.

Solvent Cleaning – Modified Alchohol Machines

Karl Roll is one of Europe’s market leaders in the field of industrial parts cleaning. Especially configured for use with modified alcohol, the RCTS cleaning machines provide optimum results and are suitable for a wide-range of degreasing and ultra-fine cleaning tasks. These machines work by flooding the chamber with hot modified alcohol solvent either with pressure media circulation or ultrasound. Steam degreasing is then applied, followed by cleaned parts being dried in a vacuum.

Ultrasonic precision cleaning

The EVO is a fully automated solution for the most demanding of cleaning requirements. Adaptable to a wide variety of cleaning tasks, the various process modules for ultrasonic cleaning, rinsing and drying can be individually customers for an optimal cleaning process. The EVO removes various contaminants, including oil and grease, adhesive residues, particles and oxidation. Designed by our partner Elma, this machine is brilliantly versatile; it has been developed for medical technology, precision components, watches and jewellery and energy technology.

Spray wash cleaning

Typically used for MRO (maintenance, repair and overhaul) in the aerospace industry, Aqua Clean’s ACV Multi-Stage wash machine is designed to process medium to large components. The ACV utilises detergent and rinse cycles with either rotating or reciprocating spray systems to produce consistent and exceptional results.

Mafac Malta

Mafac have combined the principles of kinematic with ultrasonic technology to ensure efficient and premium results. The Mafac Malta can be configured individually for customer needs, and is equipped with a rotating and movable ultrasonic unit. This innovative and compact machine is perfect for small, more complex parts and difficult-to-reach surfaces.

Don’t forget to follow the link here to sign up for your free MACH 2024 ticket.

We look forward to showing you the power of Turbex solutions.