Find us at MACH 2024! 15th-19th April stand 17-331, NEC Birmingham

Turbex are excited to announce our return to MACH 2024- a showcase for UK Manufacturing.

Read more

Whether you are involved in the maintenance, repair and overhaul (MRO) of engines, airframes or interiors, Turbex has the right system to suit your needs. No other company has the same depth and breadth of experience and machine technology, to cover the complete range of geometries, size, and volume requirements for precision parts, airframes, landing gear and propulsion components.

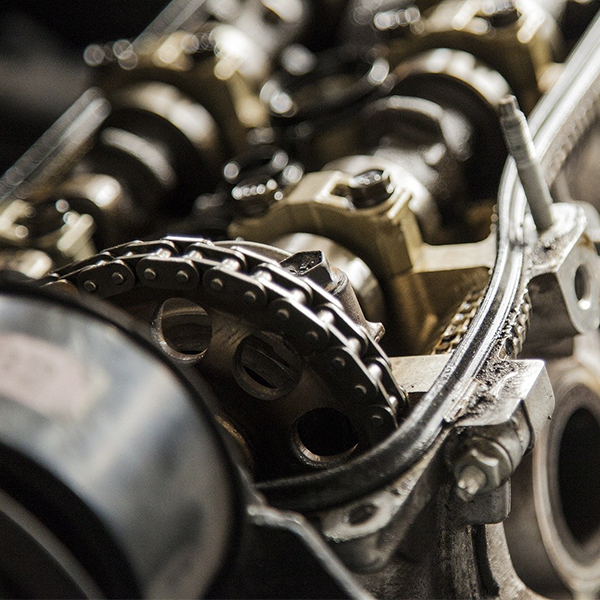

Engine, powertrain and exhaust components are ideal for washing, degreasing and drying in Turbex machines. We supply turnkey installations to meet production rates and cleanliness specifications, maximising your machine up-time and productivity to achieve the highest possible margins.

Turbex has the expertise to deliver complete decontamination of both parts in service and repair depots serving the rail industry. We are fully able and equipped to supply to companies specialising in a major overhaul of rolling stock.

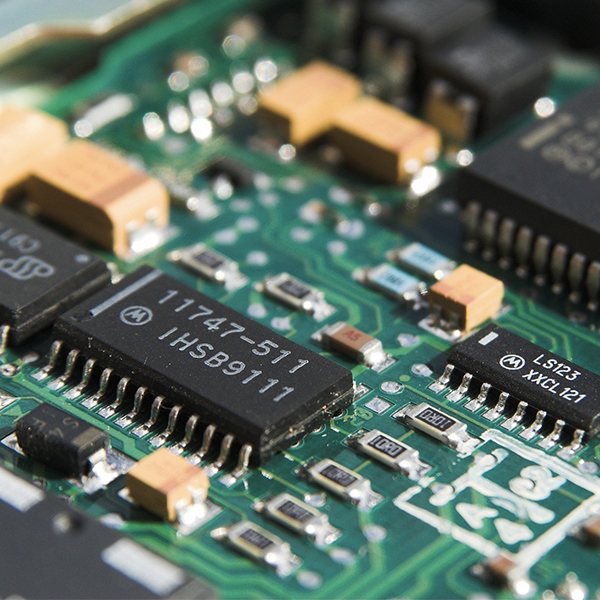

Multi-stage cleaning of electrical and electronic components, often with ultrasonics, is a key service that we offer. Especially crucial for high-end military and aerospace applications, Turbex has extensive experience with providing this service for both industries.

High precision and exacting standards with fine tolerances are essential to meet regulatory requirements. Turbex has proven washing systems for inter-process or final cleaning of items, ranging from replacement joints to surgical instruments.

The manufacturing process is a source for many contaminants, from cutting oils and swarf to grease, dirt, and forming lubricants. Where flexibility, capability and productivity are all imperative, Turbex has a washing process to address each and every cleaning requirement.

Turbex can supply systems for precision cleaning of optics due to its wide range of ultrasonic machinery. Ranging from simple bench-top units to multi-stage cleaning and drying lines with PLC controlled automation, Turbex will have the right machine to meet your needs.

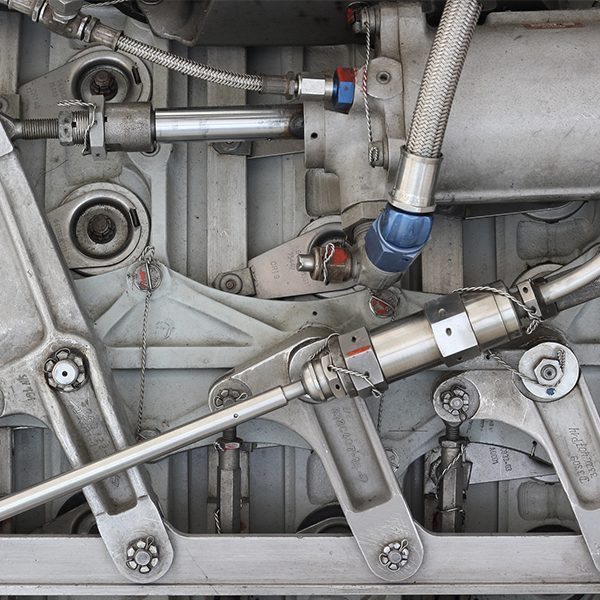

Hydraulic components require high levels of cleanliness due to the nature of their operation. Whether it is inter-stage or final cleaning Turbex has a washing process to achieve each and every requirement.

Turned part machining requires effective cleaning of components with fine tolerances to make sure they work as designed. From dislodging debris and thorough degreasing to providing surface cleaning, Turbex can supply effective systems for meticulous cleaning within the turned part industry.

The fine mechanisms in watches and jewellery need the right equipment for precision cleaning, which Turbex can provide. We understand the intricacies of your components and the fine tolerances that are required and can provide a range of careful washing and drying solutions that are tailored to your industry.

Whether it’s fine ultrasonic cleaning for the nuclear energy industry, robust degreasing for oil and gas, or alternative cleaning solutions for renewables, Turbex has a range of machines that can be modelled to your exact requirements.

With something as important as defence, you need to put your trust in the experts. Turbex can provide a robust solution for cleaning military weapons, both large and small to aircraft and ship engines. Our unrivalled expertise across a range of applications in the Navy, Airforce and the Army, means we can offer a bespoke cleaning package tailored to you.

Speak to someone at Turbex today to find out how we can support you and advise you on the best approach for your requirements.

Contact usLet’s chat to find out how we can help your business to grow.