Turbex can help you

High precision and exacting standards with fine tolerances are essential to meet regulatory requirements within the medical field. Turbex has proven washing systems for inter-process or final cleaning of items, ranging from replacement joints to surgical instruments.

Medical applications

In-process cleaning

Final cleaning

Passivation lines

Cleaning of implants, endoscopes and surgical instruments

Advantages at a glance

FDA 21 CFR Part 11 compliant

Data logging and traceability

Cost-effective and efficient cleaning process

Environmentally friendly

A proven track record within the industry

Units and lines can be validated for each cleaning process step

Multifrequency ultrasonics for improved cleaning performance

High-quality manufacture with innovative design principles

Stainless steel construction

Full after-sales support

Application support to ensure the optimum cleaning process

The Turbex line is so efficient that nearly all components including non- critical parts can be processed in the equipment using a range of semi- automatic washing cycles

ATL director Nigel Downing

Ultrasonic cleaning systems

The intermediate and final cleaning of items such as implants, endoscopes and surgical instruments requires ultrasonic cleaning. This removes contaminants such as process residues, oil, polishing compounds, particulate, wax, and grease. A variety of liquid maintenance options ensure optimum performance time after time, and an oil separator gives the ability to use de-emulsifying cleaners. The different tank sizes make the units suitable for use in a production or maintenance environment.

Ultrasonic cleaning is ideal for removing large quantities of contamination and for cleaning tasks that require a multi-stage process. The two different multi-frequency fields ensure real flexibility for the range, which allows for high precision cleaning as well as less arduous tasks.

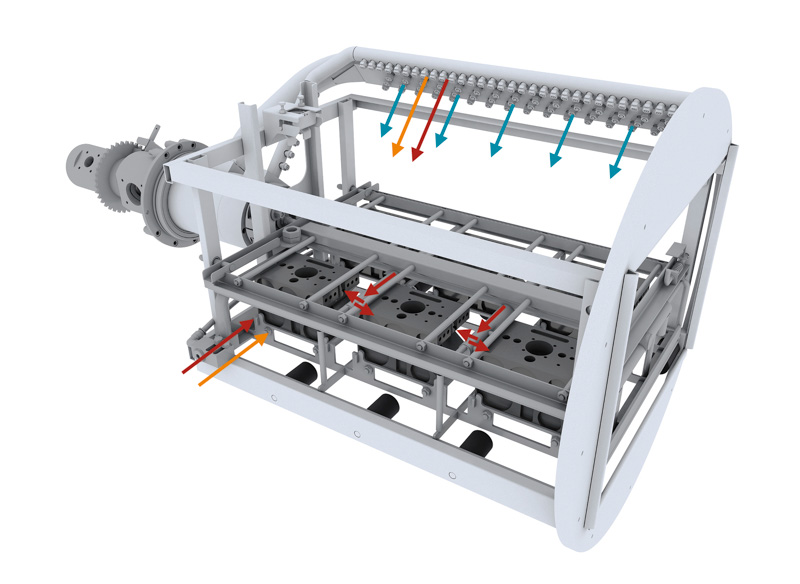

Precision cleaning with rotation

Turbex’s precision cleaning with rotation machines is perfect for inter-process cleaning of joint replacement parts, surgical instruments, and more.

Patented technology, which features the rotation of basket and nozzle systems in the opposite or same direction, sets global standards within the cleaning industry. Our machine models are each based on a high-energy principle, ensuring clean and efficient solutions tailored to your individual cleaning requirements.

The spray-flood systems in this range, the PALMA, PALMA XL and JAVA are frequently used in the medical industry. The main characteristic of the JAVA, PALMA and PALMA XL series is the patented cleaning and drying technologies.

Non-destructive testing lines

Non-destructive testing (NDT) and component cleaning are closely related. Through our experience of cleaning, we have developed an extensive knowledge of the fluorescent penetrant inspection (FPI) process and the systems required. Our FPI systems utilise our know-how of automation and process control to provide consistency and traceability time after time.

Solvent cleaning systems

When a large amount of oil and grease needs to be removed, Turbex’s solvent cleaning machines can provide the right solution for your industry. Solvent cleaning produces optimum results every time, for a wide variety of operations. Whether it’s degreasing surfaces, or removing particles and contaminants – such as lubricants, swarf and particulate – our range of solvent cleaning machines and detergents are more than up to the job.

Drying systems

A variety of drying techniques are available, including hot air, infrared and vacuum drying. Through discussion, we can advise on the most cost-effective drying technique for your application.

Get in touch…

Let’s chat to find out how we can help your business to grow.