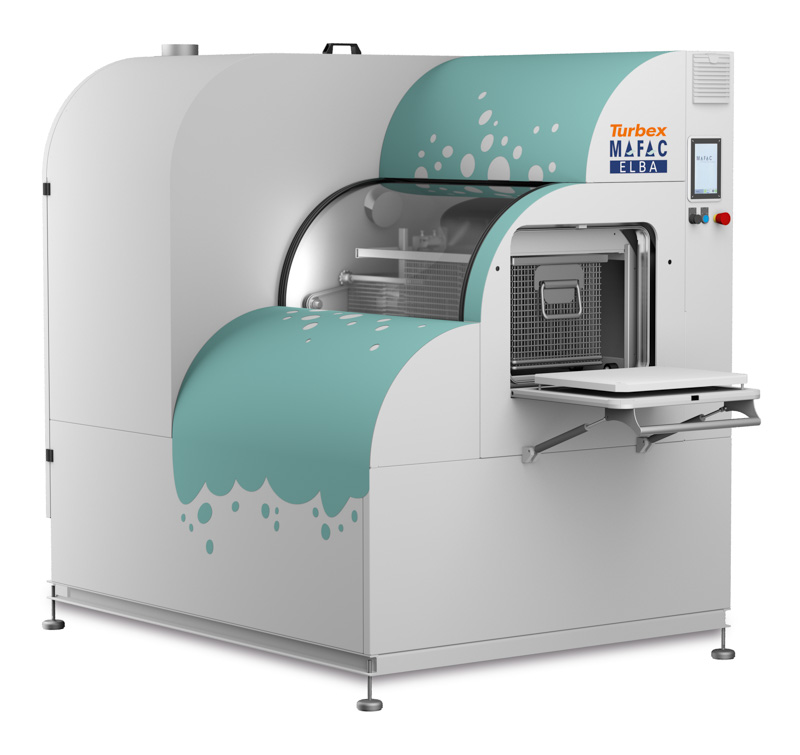

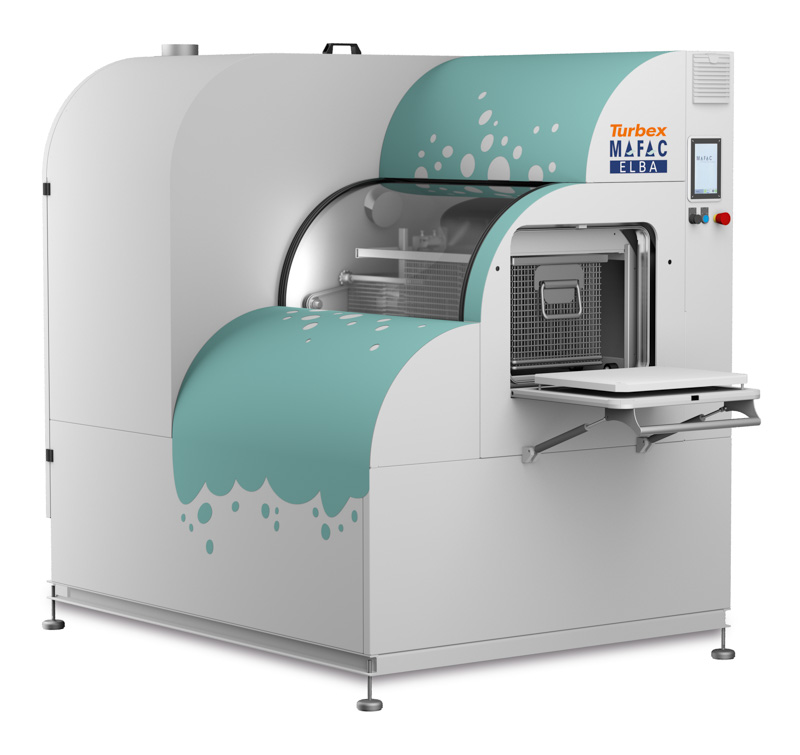

Mafac Elba

Overview

The Elba is your reliable partner in mastering the versatile requirements of industrial parts cleaning. It can be used for a wide range of cleaning applications, and the tried and tested dual wash tank system is compact, powerful, and eco-friendly. Elba cleaning systems provide exceptionally clean results after machining processes and are used extensively across a wide range of industries including the automotive industry, end-users in electronics, machine shops, electro-plating and hardening and coating shops. The system cleans bulk materials and single workpieces reliably, as well as batches of stainless steel, mild steel, cast iron, non-ferrous metals or even plastics.

The dual wash tank technology offers a wide range of options for efficient processes, providing flexibility where it is needed. The two wash tanks can be used for washing and rinsing and offer a rotating pulsed compressed air blast drying system or a stationary hot air drying system; both high-quality options in drying technology which make sure we always meet our customers’ system requirements.

Get in touch…

Let’s chat to find out how we can help your business to grow.