What is non-destructive testing (NDT)?

NDT is used to detect surface defects in a range of metals and non-porous materials. The most common of which is fluorescent penetrant inspection (FPI), also known as penetrant flaw detect (PFD)

What can non-destructive testing be used for?

NDT is used on a range of components, primarily in the aerospace industry, for example, engine parts, aerostructures, wheel hubs, brake parts, landing gear. It is also used on automotive components.

How does non-destructive testing work?

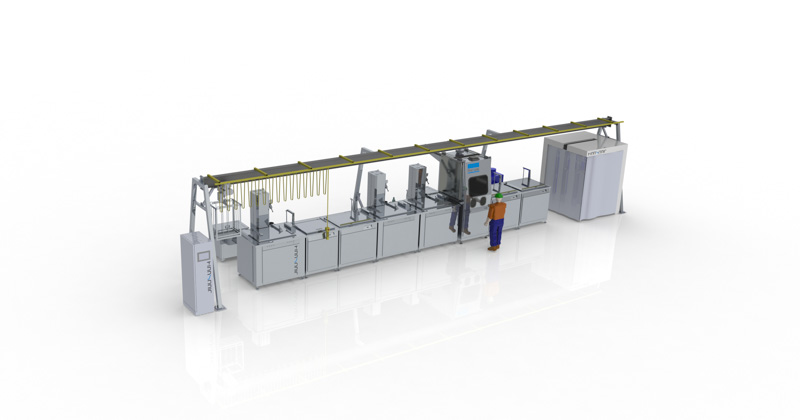

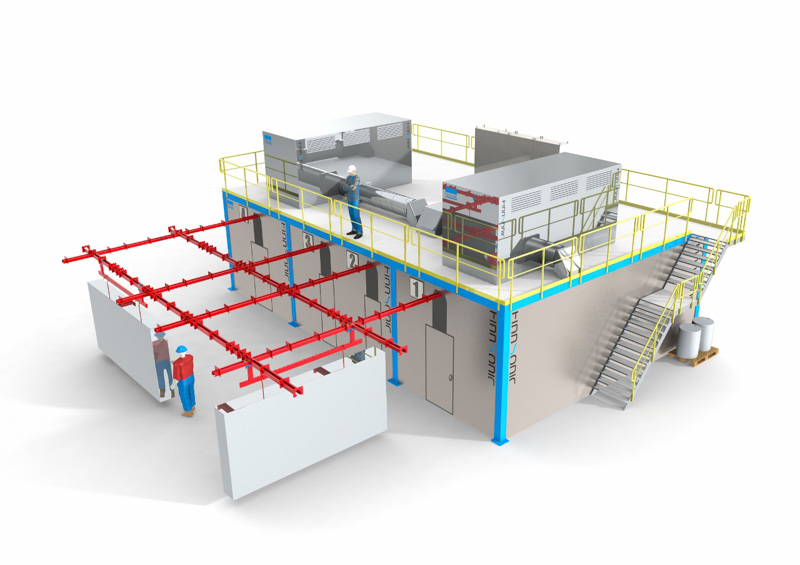

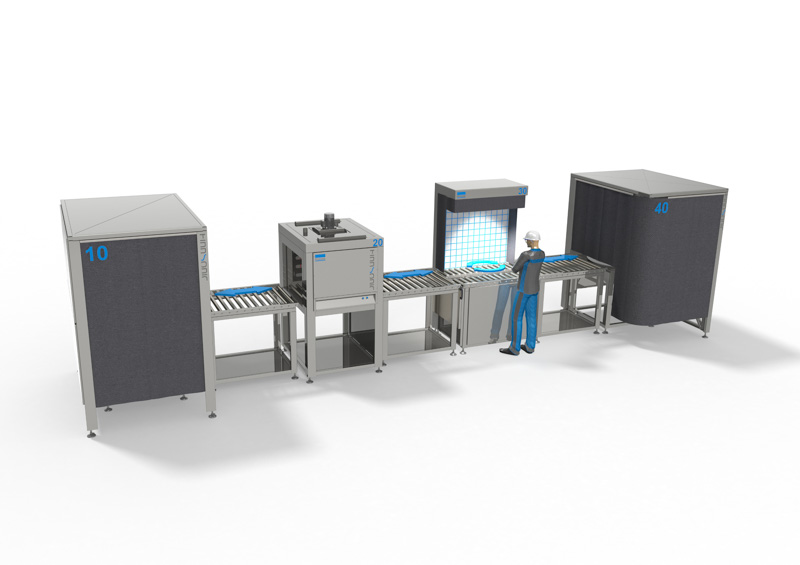

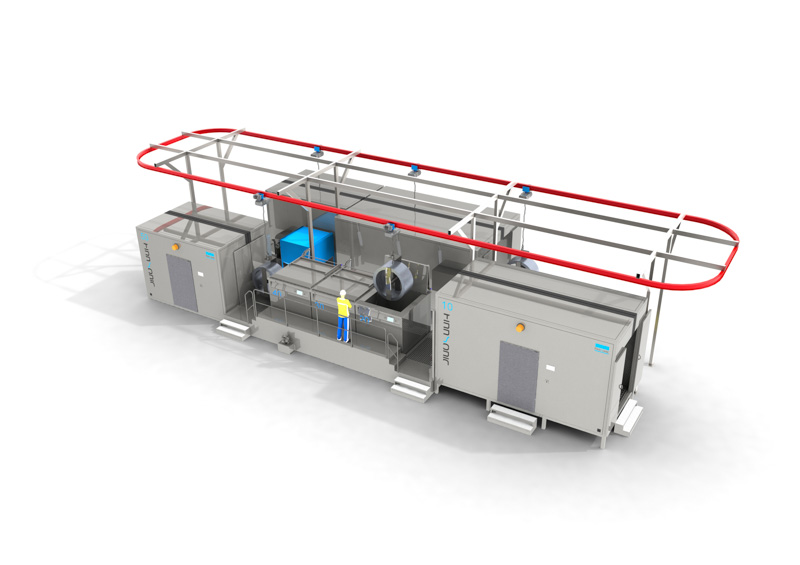

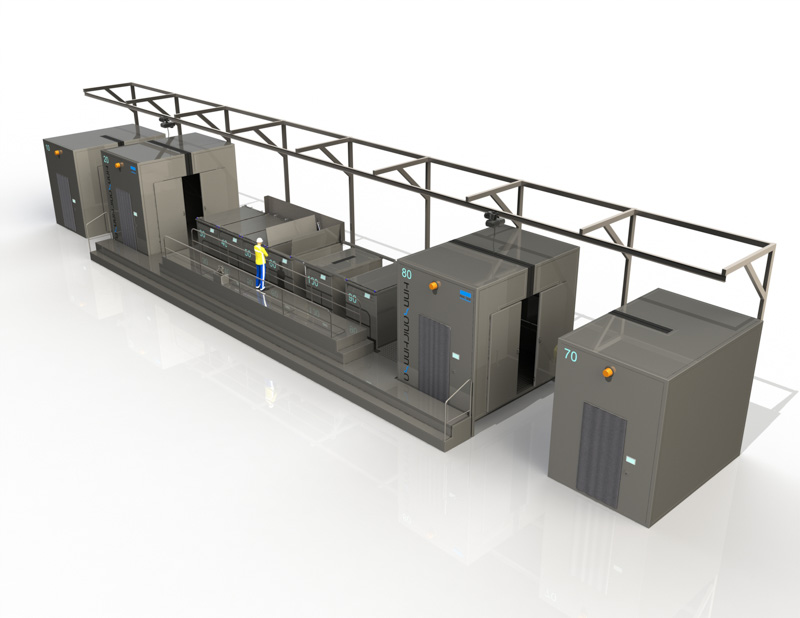

Turbex’s lines use a combination of automation and manual operation to provide a streamlined and maintainable NDT process.

More about fluorescent penetrant inspection (FPI)

Turbex’s lines use a combination of automation and manual operation to provide a streamlined and maintainable NDT process. Fluorescent penetrant inspection (FPI) is an effective and fast method to inspect critical parts for defects before or after heat treatment.

Main applications:

Engine parts

Aerostructures

Wheel hubs

Brake parts

Landing gear

Automotive parts

Advantages at a glance:

Intelligent combination of both automatic and manual handling

User-friendly design

Low operational costs

Eco-friendly with low consumption of processed chemicals

Traceability and reliability of inspection

Durable, safe and effective

Get in touch for an informal chat and we’ll apply our decades of expertise to advise you on the right approach for you.

Get in touch…

Let’s chat to find out how we can help your business to grow.