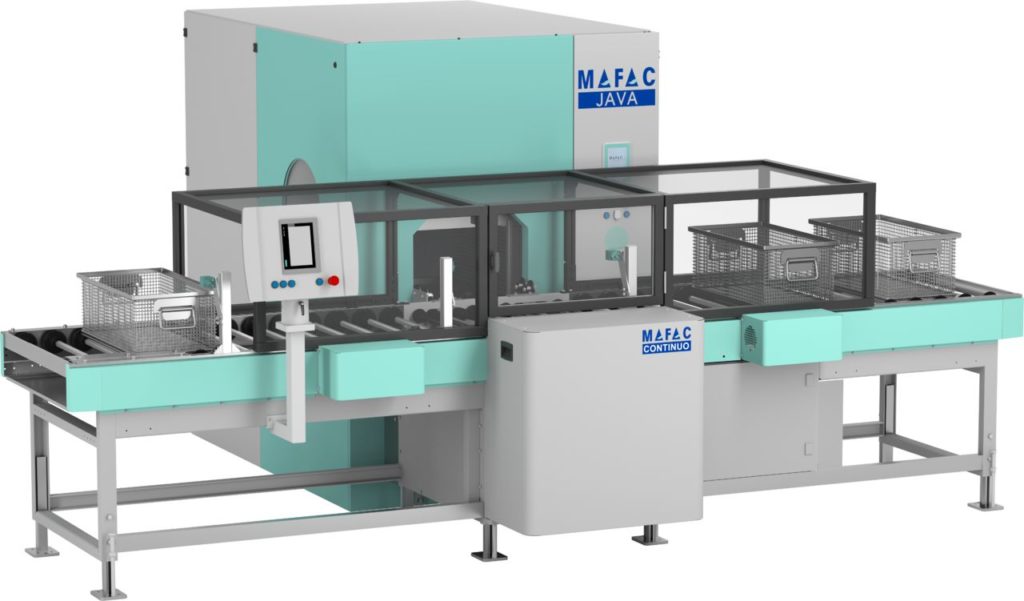

MAFAC CONTINUO is a new transfer system made up of modules that can be integrated into the production environment in a flexible manner.

Turbex partner MAFAC is extending its range. The company recently introduced MAFAC CONTINUO, a transfer system developed to speed up its processes and create a more efficient wash for its customers.

Operating in accordance with a flexible waiting queue principle, the system is optimally tuned to the MAFAC parts washers and enables operation with up to five goods baskets or workpiece carriers in the loading and unloading area. This ensures reliable, unmanned transporting, buffering and separation of workpiece carriers with material to be cleaned.

Johannes Maier, MAFAC design engineer explains, “With the automatic MAFAC CONTINUO, we offer our customers a compact solution to ensure an optimum use of the parts washer. In addition, the manpower requirements are reduced. At the same time, the principle ‘all-from-one-source’ contributes essentially to an even more customer-friendly service.”

Applications for MAFAC CONTINUO

The system can be used across all sectors of industry, and especially in areas with a high volume of parts. Furthermore, to meet individual requirements, it can be expanded in modular fashion.

The standard configuration of the MAFAC CONTINUO combines the important functions required for an efficient and space-saving transfer of dirty components into the MAFAC parts washer and of baskets with cleaned parts into the removal station. As well as this, it is possible to transport baskets or workpiece carriers of varying dimensions with a batch weight of up to 100 kg.

To find out how the MAFAC CONTINUO can speed up your processes, get in touch with the Turbex team today.