What is ultrasonic cleaning?

Ultrasonics is the term used for vibrations that are inaudible by the human ear. It is commonly used in cleaning applications and for cleaning components with a complicated geometry where standard cleaning principles or manual cleaning methods can sometimes fail.

How does ultrasonic cleaning work?

Transducers in the tank transmit high and low-pressure waves into the liquid. The compound structure

of the liquid tears apart when the vibrations reach a certain level and create microscopic vacuum

bubbles near the surface of the desired object. These violently implode and direct a pressure jet

towards the surface of the component – a process called cavitation. Ultrasonic cleaning gently and

effectively removes dirt particles from all completely immersed areas, even from the smallest grooves

and holes. The use of ultrasonics can reduce the cleaning time by up to 90%.

When to use ultrasonic cleaning?

Ultrasonics is excellent for all precision cleaning tasks, especially for companies within the:

- Medical field

- Precision optics industry

- Aerospace industry

- Electronics and semiconductor production industries

- Watch and jewellery industry

- Manufacturing of precision components

- Automotive industry

- Nuclear energy sector

- Rail industry

Products

-

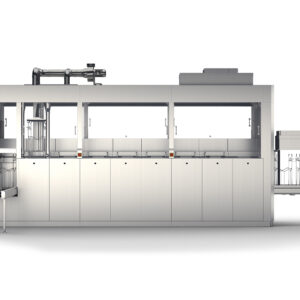

Evo Automated Systems

View product -

Evo Manual Systems

View product -

Evo Precision Systems

View product -

Bespoke Systems

View product -

Ultra Sonic Cleaning Tank

View product -

ST Floor Standing Machines & Peripherals

View product -

Select Range Benchtop Machines

View product -

P Range Benchtop Machines

View product -

TT Benchtop Machines

View product -

LSM Solvent Machine

View product