Evo Precision Systems

Overview

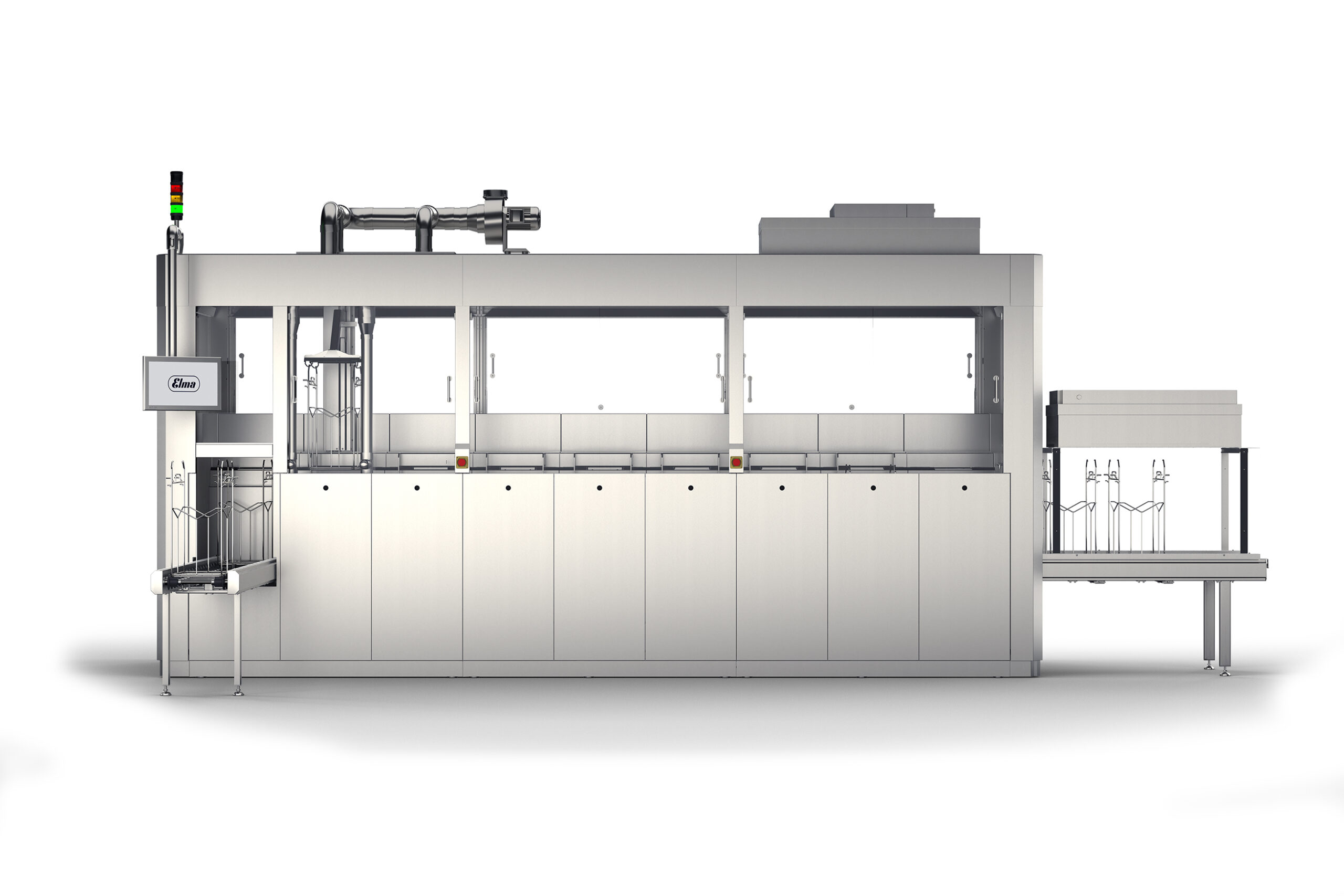

The Evo Precision range has been created for when the cleanliness requirement is of the highest level, such as before optical coating or medical implant technology. The standard units have rounded tank corners, polished internal surfaces and specially designed rigid pipework which are all designed to avoid particle entrapment within the system. Two different multi-frequency options (25/45Khz or 37/130Khz) ensure even the most demanding requirements are met.

The Evo precision range comes in three different sizes, ranging from between 60 and 170 litres. The machine can be operated either manually, via the integrated control panel with LCD or automatically using an IPC control system and an integrated data logger.

The Evo precision is capable of adapting to changing requirements thanks to its modular design and accessories that are designed explicitly for ultra-fine cleanings. These include hot-air dryers with HEPA filters, infrared or vacuum dryers or enclosures with laminar flow boxes.

Get in touch…

Let’s chat to find out how we can help your business to grow.